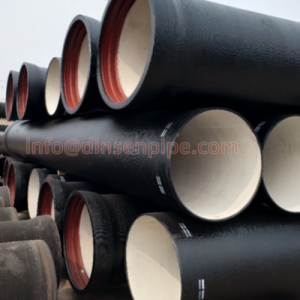

For any pipe connection, the joint type is the core, directly determining the system’s sealing, stability, and construction efficiency. For ductile iron pipes, the three most commonly used joint types are the T-shaped socket joint, the flange joint, and the self-anchor joint, each playing an important role in their respective applications.

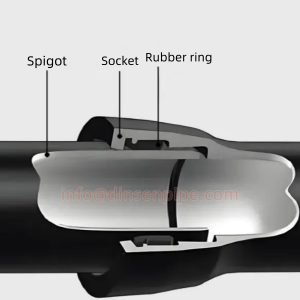

1. T-Type Joint

● Joint Introduction:

The T-joint, also known as a spigot-and-socket joint or slip-on joint, is a flexible joint and the most widely used connection method for ductile iron pipe. Its design is straightforward: a socket (with a groove) on one end and a spigot on the other. Once the spigot is inserted into the socket, a pre-installed rubber seal creates a seal. Typically, no additional fasteners are required, and stability is maintained by the pipe’s own weight and the surrounding fill.

Interface Features:

- Easy Installation: Simply push the plug into the socket, and the rubber ring automatically seals. Installation is fast and requires minimal tools or skills.

- Flexible Connection: Allows 3°-5° of deflection, adapting to minor foundation settlement or angle adjustments.

- Low Cost: Simple structure and minimal components ensure low production and installation costs.

● Applicable Scenarios:

Due to its economical and practical nature, the T-type joint is almost standard in municipal piping. It is particularly suitable for:

- Urban water supply networks:

For example, water mains, where pressures are moderate and construction volume is high, the T-type offers significant efficiency and cost advantages.

- Underground drainage systems:

For buried sewage pipes, where foundations may fluctuate slightly, the T-type’s flexibility is just right.

- Conventional low-pressure applications:

General projects that do not require exceptionally high pullout resistance.

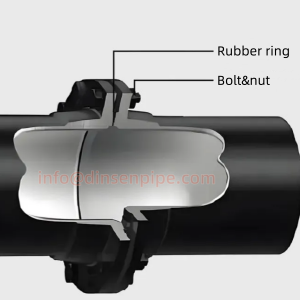

2. Joint Introduction:

Flange joints are rigid joints. Tightening the connecting bolts forces the flange to squeeze the sealing ring to achieve a seal. They are commonly found in piping systems that require connection to valves and other accessories or are frequently disassembled.

● Interface Features:

- Secure Connection: The bolted connection provides exceptional stability, withstands high pressure and external forces, and resists loosening.

- Removability: The connection can be separated by loosening the bolts, facilitating maintenance and replacement.

- Rigid Design: It resists deflection, requiring high pipe alignment and precise installation.

- Weight and Cost: The flange increases pipe weight and material cost, making installation more complex.

● Applicable Scenarios:

For example, inlet and outlet pipes in water treatment plants require seamless connections with pumps and valves, making flange connections the preferred option.

Industrial Piping Systems:

High-pressure or high-temperature water pipes within factories often require regular maintenance, making flanges highly practical due to their ease of installation and removal.

In-Ground Fixed Piping:

Overhead or indoor piping where foundation settlement is not a concern.

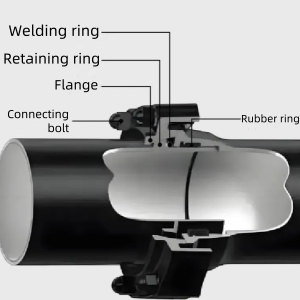

3. TF Self-Anchoring Joint

● Joint Introduction:

The self-anchoring joint is an upgraded version of the T-joint. It utilizes the sealing structure of the T-joint and adds accessories such as a weld ring at the socket end, a movable opening retaining ring, a special pressure flange, and connecting bolts. This makes the joint more resistant to pullout and can also be used where buttresses are unavailable.

● Interface Features:

–Flexibility and Pull-Out Resistance:

–Allows 3°-5° deflection while resisting pipe pull-out caused by high internal pressure or external forces.

–High Safety:

–The locking design enhances the overall stability of the pipeline, especially in dynamic environments.

–Moderate Installation Difficulty:

–While slightly more complex than the T-type, it does not require the same bolting as the K-type, making installation manageable.

–Higher Cost:

–The locking device increases manufacturing and material costs, making it more expensive than the T-type.

● Applicable Scenarios:

- High-pressure, long-distance pipelines:

For example, interregional water supply pipelines, where water pressure is high and distances are long, self-anchoring can prevent pipe unseating.

- Geologically Complex Areas:

In earthquake-prone areas or soft soil foundations, pipelines are susceptible to external forces, and self-anchoring provides additional protection.

- Crossing Projects:

For example, pipelines crossing rivers or roads, where external tension is high, self-anchoring can stabilize the structure.

To sum up, the T-type dominates daily engineering with its simplicity and practicality, the flange meets the equipment connection needs with its firmness and detachability, and the self-anchoring type copes with complex challenges with its flexible and pull-out resistance. Each has its own advantages and characteristics.

T-Type Joint, Flange joints, TF Self-Anchoring Joint, ductile iron pipe, DI pipe,

Post time: Oct-17-2025