Tensile testing of metal materials is a core method for evaluating their mechanical properties and is of great significance. By measuring parameters such as tensile strength, yield strength, and elongation, it quantifies the material’s load-bearing capacity and plastic deformation characteristics. It provides a safety basis for engineering design and ensures structural reliability. It also serves as a crucial quality control tool, verifying the stability of production processes and ensuring compliance with international standards. Furthermore, it can predict the risk of material failure under complex loads and provide critical data support for the development of new materials.

The following is a comparison of tensile testing methods for ductile iron pipes and SML pipes, both of which help ensure product quality and long-term use in various real-world scenarios.

1. Sample Variations

The thickness and test rod diameter of ductile iron samples are as follows:

| Casting type | Nominal diameter of test bar (mm) | Diameter limit deviation (mm) | Diameter tolerance (mm) |

|

Ductile iron pipe wall thickness (mm) e<6 6≤e<8 8≤e<12 12≤e |

2.5 3.5 5.0 6.0 |

±0.06 |

0.03 |

| Non-ductile iron pipes, fittings, and accessories: - Integral casting specimens: - Split casting specimens: For specimens with a thickness of 12.5 mm, the casting thickness must be less than 12 mm. For specimens with a thickness of 25 mm, the casting thickness must be ≥ 12 mm. |

5.0 6.0 12.0 or 14.0 |

±0.06 ±0.06 ±0.09 |

0.03 0.03 0.04 |

Note: The test bar is made from the machined specimen, representing the metal in the middle thickness of the specimen. It includes a cylindrical portion. The diameter of the cylinder is shown in the table above. The gauge length of the test bar is at least 5 times its diameter. The end of the test bar should be suitable for mounting in the testing machine fixture. The surface roughness of the cylindrical portion of the test bar is Rz ≤ 6.3.

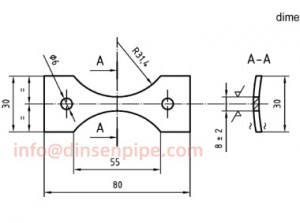

The SML pipe is made of grey cast iron and its specimen should conform to the following figure:

Note: To obtain test results that are as representative of the finished product as possible, the test specimen should be taken from the SML pipe or SML fitting and cut parallel to the axis of the tube or fitting. The original cross-sectional area of the specimen should be measured. The width and thickness of the cross section must be accurately measured to 0.1mm before testing.

2. Differences in the test process

Although both tensile tests are performed using a universal tensile testing machine, the fixtures used are different. The tensile test fixture for ductile iron is shown below:

The SML pipe and fitting tensile test fixture is shown below:

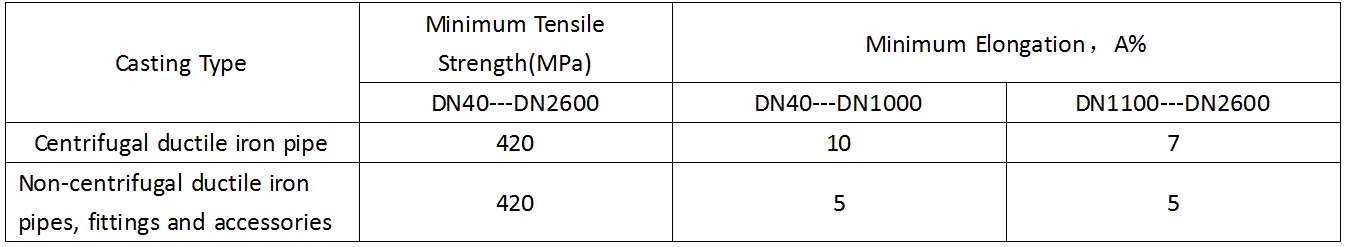

3. Differences between Test Results and Material Properties

The smelting and manufacturing process of ductile iron is the product of years of technological accumulation and rigorous work ethic. Our company produces high-quality ductile iron pipes, with a spheroidization rate of 90% or higher. Tensile testing reveals tensile strengths between 460MPa and 490MPa, and elongations between 10% and 17%. According to EN545 and ISO2531 standards, a tensile strength of 420MPa or higher and an elongation of 5% to 10% or higher are considered acceptable. The standard tensile strength and elongation are as follows:

SML pipes and fittings are primarily made of gray cast iron. The flake graphite structure within the gray cast iron absorbs water vibration, resulting in drainage noise levels at least 10dB lower than PVC pipes. They also offer excellent high-temperature resistance, exceeding 1,000°C. The sealing rubber rings remain functional even at 70°C continuous or 120°C intermittent discharge, with thermal deformation only one-seventh that of PVC pipes. They also offer excellent tensile strength, impact resistance, and abrasion resistance, at least five times that of PVC pipes.

According to the EN877 standard, the mechanical properties of SML pipes and fittings are as follows:

| Casting type and material | Minimum tensile strength

(Mpa) |

| Pipe: Gray cast iron | 200 |

| Fitting: Gray cast iron | 150 |

SML pipes and fittings, PVC pipes, EN877 SML pipe and fitting tensile test ,SML fitting, EN545 ISO2531 ductile iron pipes and SML pipes, ductile iron samples, SML pipe, grey cast iron pipe,

Post time: Sep-22-2025