As a high-end piping brand solution provider, DINSEN understands that every pipe carries the weight of safety, durability, and trust. To this end, we have built a “triple quality protection” system from materials to finished products—namely, rigorous factory inspection, scientific sampling inspection, and authoritative type testing—to ensure that every product delivered to our customers represents DINSEN’s highest quality standards.

Factory inspection is the first and most direct checkpoint for DINSEN products entering the market. We conduct a comprehensive “check-up” on every ductile iron pipe and fittings, ensuring that every single product meets basic technical specifications and appearance requirements, preventing defective products from entering the market.

Meanwhile, to ensure the continuous stability and consistency of the production process, DINSEN implements rigorous sampling inspection during production and in the finished product warehouse, conducting more in-depth performance tests than factory inspection. This is a continuous monitoring and proof of DINSEN’s superior manufacturing process.

If factory and sampling inspections focus on the “manufacturing quality” of the product, then type testing is the ultimate test to verify the product’s “design quality.” Type testing is a series of comprehensive and rigorous tests conducted on a sample that represents a prototype of a mass-produced product, according to a product standard (such as EN545, ISO2531, etc.), to verify that its design, materials, structure and performance fundamentally and fully comply with or even exceed all the requirements of the standard.

In EN 545, the sealing performance test of flexible joints (such as T-type and K-type joints) is one of the core items of type testing. The procedure for the “flexible joint sealing test under positive internal pressure” is rigorous and demanding:

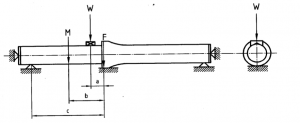

The test involves assembling two pipe sections as shown in the diagram below, each at least 1 meter long. The test assembly is filled with water and easily vented. The pressure is continuously increased to (1.5 FPA + 0.5) test pressure and maintained for at least 2 hours. During this period, a comprehensive inspection of the joints must be performed every 15 minutes. All necessary safety precautions must be taken during the pressure test. Simultaneously, a shear force of 30 times the DN is applied.

Judgment criteria: No visible leakage or pressure drop should occur at the joints throughout the entire test and at the end. Successfully passing this test means that the flexible joints of DINSEN ductile iron pipes can provide absolutely reliable sealing even under the most unfavorable stress conditions, ensuring the long-term safety and leak-free operation of the water supply network.

Factory inspection, sampling inspection, and type testing—this three-pronged quality control system is progressive and indispensable. Together, they form a complete quality loop for DINSEN ductile iron pipes, from “excellent design” to “perfect delivery.”

Post time: Dec-01-2025