The cement-mortar linings for ductile iron pipes is primarily used to prevent corrosion and scaling on the inner wall of the pipe, ensure water quality, and reduce hydraulic friction losses. However, the core European standard EN196-1 specifies the method for determining the strength of cement mortar, which is one of the most fundamental and important criteria for evaluating cement mechanical properties (such as compressive and flexural strength).

The testing process can be divided into the following main stages: preparation, batching, mixing, molding, curing, fracture testing, and result calculation.

Experimental Procedure 1.Mixing Steps: Add water and cement, and mix at low speed for 30 seconds ;

Add sand evenly within the next 30 seconds (starting with the coarsest grade), and mix at high speed for 30 seconds;

Pause for 90 seconds (scrape off any mortar from the blades and the pot wall within the first 15 seconds);

Stir at high speed for 60 seconds. The time tolerance for each stage is ±1second

2. Molding (Vibrating Table):

Secure the empty test mold and mold sleeve on the vibrating table;

Load the material in two layers, approximately 300g per tank in the first layer, and vibrate 60 times;

Load the second layer and spread it evenly, then vibrate 60 times again;

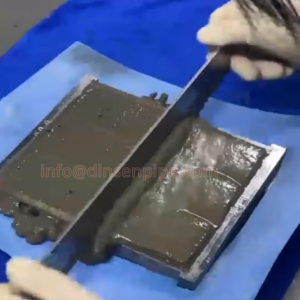

Remove the mold sleeve, scrape off any excess mortar, and smooth the surface.

3. Numbering: Identify the specimen number and location. Specimens in the same test mold can be of different ages. 4. Cleaning: Clean the mixing pot, blades, and discharge funnel before testing or when changing cement.

5. Curing:After numbering, place the test molds in a curing box (with the grate horizontal and the scraped surface facing upward).

Test specimens aged 24 hours should be removed from the mold within 20 minutes before breaking.

Test specimens aged 24 hours or more should be removed from the mold within 20-24 hours after forming (record the time).

After demolding, place in water for curing (test specimen spacing ≥ 5 mm, top surface water depth ≥ 5 mm).

Test specimens of the same type should be cured in the same tank, maintaining a constant water level (do not replace all the water).

Test specimens of the desired age should be removed 15 minutes before testing, cleaned of sediment, and covered with a damp cloth.

Result Processing and Reporting Compressive Strength: Report the arithmetic mean of the compressive strengths of the six half-specimens, accurate to 0.1 MPa. If any result differs from the mean by more than ±10%, it will be discarded. If fewer than three valid results are left after these discards, the test must be repeated.

Post time: Sep-16-2025