In modern urban life, the sanitation and environmental protection requirements of urban water supply must be taken into consideration. To prevent rust from contaminating tap water and to protect the pipes from corrosion from within, the inner wall of the pipes must be coated with an internal coating. Below we will analyze the internal corrosion protection of ductile iron pipes in detail.

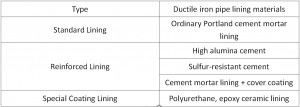

Type of Internal Corrosion Protection

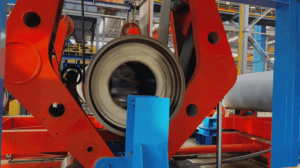

Cement lining is applied using a centrifugal coating process. This method creates a smooth, evenly applied surface, provides a strong bond with the pipe wall, and resists peeling. Anti-corrosion linings can be classified into three types based on the corrosive nature of the water they transport:

Lining anti-corrosion coating range (see table below)

1. Standard Lining

Application: Suitable for most raw and drinking water applications

Lining Material: Ordinary Portland Cement Mortar Lining

Cement mortar is an active anti-corrosion coating that releases alkaline substances upon contact with water, causing passivation on the inner wall of the ductile iron pipe, providing electrochemical protection for the substrate.

2. Reinforced Anticorrosion Lining

Application: Soft water, slightly acidic water, highly abrasive water, and other corrosive water types

Lining Materials: High-alumina cement, sulfur-resistant cement, cement mortar lining + topcoat

High-alumina cement: A commonly used reinforced anticorrosion lining with strong resistance to sulfate attack, suitable for sewage, wastewater, and water containing chemicals.

Sulfate-resistant cement: Resistant to sulfate attack, suitable for water exposed to sulfate attack.

Cement Mortar Lining Epoxy Seal: A water-based epoxy coating is sprayed and cured onto the surface of the cement mortar lining. It offers excellent corrosion resistance and ensures the quality of the conveyed water remains uncontaminated.

3. Special Coating Lining

Applications: Suitable for highly specialized applications or corrosive water quality, industrial drainage, and particularly arid regions, where the material’s advantages are significant.

Lining Materials: Polyurethane, epoxy ceramic lining. Highly wear-resistant, corrosion-resistant, and chemically resistant, it offers a smooth surface and low drag coefficient, meeting environmental requirements.

Cement curing: After centrifugal coating, the pipe with cement lining is placed in an environment with a temperature of 20±3℃ and a humidity of more than 95% to accelerate the curing of the cement lining. The compressive strength of the cement mortar lining is not less than 50MPa after 28 days of curing.

Quality control requirements for the inner anti-corrosion layer of ductile iron pipes

Testing tool: Cement coating portable intelligent ultrasonic thickness gauge

Qualification standard: Cement lining thickness must meet the requirements in the table below.

Standard requirements (ISO 2531, EN 545, GB/T 13295, EN 598 cement lining thickness (mm))

The inner lining is free of bubbles, internal flow, laitance, floating sand, eccentricity, peeling, cracks, iron sticking, and debris. The chamfers of the inner lining at the socket are qualified and smooth.

In general, the inner wall anti-corrosion coating of ductile iron pipes must have excellent hydraulic and corrosion resistance. When selecting the inner lining, factors such as the corrosiveness of the fluid to be conveyed, the water flow rate, and the ambient operating temperature should be considered. DINSEN can provide customers with customized internal anti-corrosion coating solutions based on different operating environments.

Post time: Sep-26-2025