1. Ductile Iron Sliding Flexible Joint

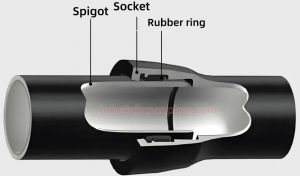

The most common joint type for ductile iron pipe, the T-joint relies on contact pressure between the rubber ring and the socket and spigot (partially generated by pre-compression during installation) to create a seal against fluids. The socket design takes into account the positioning and deflection angle of the rubber ring, allowing for adaptation to certain foundation deformations and providing a certain degree of vibration resistance. It features a simple structure, easy installation, and excellent sealing properties. However, its disadvantage is its limited ability to prevent pipe slippage, as the joint cannot withstand axial forces. Therefore, support piers are required at pipeline bends to resist axial forces.

T-shaped socket joints are widely used in ductile iron pipes. They are easy to install, cost-effective, and allow for small angles of deflection. Installation is simple: simply push the spigot into the socket, and the rubber seal automatically seals. This significantly speeds up installation while reducing tool and worker skill requirements. The following figure is a cross-sectional view of the ductile iron socket and spigot fitting:

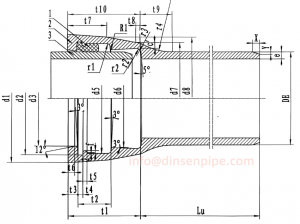

- DE is the outer diameter of the ductile iron pipe socket. d1 is the outer diameter of the ductile iron pipe socket.

- d2 is the inner diameter of the rubber ring seal groove in the ductile iron pipe socket.

- d3 is the inner diameter of the ductile iron pipe socket.

- d5 is the inner diameter of the ductile iron pipe socket and the rubber ring fitting.

- d6 is the inner diameter of the ductile iron pipe socket at the end stop of the socket.

During design and manufacturing, the socket end d3 must be slightly larger than the spigot outer diameter DE to ensure proper installation clearance. The inner diameters d2 and d3 must be within tolerance. The rubber rings on the socket and spigot are constructed from a combination of hard and soft rubber. The hard rubber portion provides the necessary support and centering for the pipe joint, ensuring that the rubber ring is properly compressed to generate a preload of 1-5 MPa, preventing fluid leakage within the pipe. As the fluid pressure within the pipe increases, the rubber ring further deforms, increasing the contact pressure to 15-25 MPa, creating a pressure-enhancing effect and tightening the pipe system seal.

2. Ductile Iron Pipe Length

The standard effective length of ductile iron pipe under the EN545 standard is 6 meters, a common specification currently adopted by most manufacturers both domestically and internationally. To facilitate container transportation, Chinese-produced pipes are typically 5.6 or 5.7 meters in length, as agreed upon by both suppliers and buyers. Indian-produced pipes are typically 5.5 meters in length.

Post time: Sep-23-2025