Cast iron pipes undergo adhesion testing and hot and cold water cycling tests in accordance with EN877, primarily to assess the long-term reliability and durability of their anti-corrosion coating systems, particularly under actual operating conditions. These tests typically target coatings applied to the interior and exterior surfaces of SML pipes (such as epoxy resins, polyurethanes, and cement mortar linings). Adhesion testing directly measures the bond strength between the coating and the base metal of the cast iron pipe. Hot and cold water cycling tests simulate the cyclical temperature fluctuations experienced by pipes in actual use, assessing the long-term stability of the coating system under these alternating thermal stresses.

Adhesion Testing

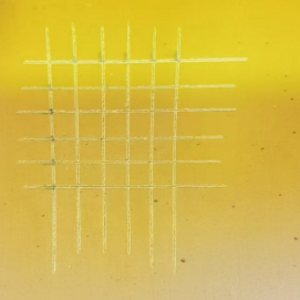

The adhesion of the coating shall be checked only on samples coming from finished products by a crosscut test in accordance with EN ISO 2409, in the following way:

- test sample: section minimum100 mm long cut from a coated pipe or fitting preferably of a size at least DN 100;

- number of cuts: 6;

- spacing of the cuts: 2 mm (3 mm for coatings which have a minimum thickness specified by the manufacturer equal or greater than 120 µm);

- The results shall conform to Table 1.

Table 1:

Resistance to temperature cycling

The test shall be performed only on samples coming from finished products.The test assembly shall be subjected to 1500 cycles of passage of hot and cold water in accordance withfollowing schedule:

a) (30 + 1) l of water at a temperature of (93 + 2) °C over a period of 1 min, at a constant rate of flow,

b) rest and drain period of 1 min;

c)(30 + 1) l of water at a temperature of (15 + 5)°C over a period of 1 min, at a constant rate offlow,

d) rest and drain period of 1 min

The water temperature shall be measured at the point of entry. An example of a typical test set-up is given in Figure 3.

After stopping the test, the pipes and fittings shall be washed immediately to eliminate any stains.The pipes shall then be sectioned lengthwise and the internal coatings examined for degree of blisteringand rusting which shall not exceed the following levels:

Degree of blistering: Dimension 3, class 3 according to EN IS0 4628-2:

Degree of rusting: Ri 2 according to EN IS0 4628-3.

Post time: Aug-04-2025