1. Measurement of ductile iron pipe length under EN545 standard

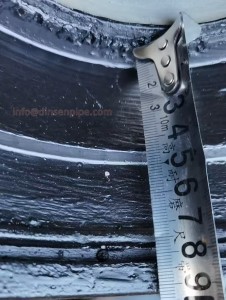

Dimensional accuracy of ductile iron pipes and fittings is fundamental to ensuring tight pipe joints and convenient installation. The EN545 standard establishes scientific and rigorous specifications for the length measurement of ductile iron pipes. According to the standard, the measurement of ductile iron pipe length requires the use of appropriate professional tools and is handled separately for two production scenarios:

- Measurement of pipes in the casting state: For ductile iron pipes cast directly from a new mold and not yet processed, their original casting length must be measured directly. This ensures dimensional control from the source of production.

- Measurement of pipes cut to specific lengths: For ductile iron pipes cut to specific predetermined lengths according to the project plan, measurement must be performed on individual finished pipes after cutting to verify that the final length fully meets design requirements.

This dual-track measurement method ensures that every ductile iron pipe shipped from the factory, whether of standard or custom length, is dimensionally accurate. This provides a fundamental guarantee for precise connection on the construction site and effectively avoids installation difficulties or the risk of joint leakage due to dimensional deviations.

2. The EN545 standard imposes stringent requirements on the straightness of ductile iron pipes.

The straightness of pipes is a key factor affecting pipeline installation quality, fluid transport efficiency, and long-term operational stability. A bent pipe introduces additional installation stress and increases the risk of leaks at joints. The EN545 standard employs a direct and efficient rolling test method to verify the straightness of ductile iron pipes.

The specific test method is as follows: The ductile iron pipe to be tested is placed on two support stands or rollers and slowly rolled axially. The standard clearly stipulates that the distance between these two support points must not be less than the standard length of the pipe. This requirement is to amplify any possible bending deformation, making it clearly visible through the pipe’s swaying or bouncing during rolling.

Through this rigorous test, any ductile iron pipes that do not meet the straightness requirements will be screened out, ensuring that every pipe delivered to the customer is perfectly straight, laying a solid foundation for laying straight and efficient water supply lines.

ductile iron pipe EN545, ductile iron pipes and fittings , ductile iron pipe specifications, cement mortar lined ductile iron pipe, ductile iron pipe sizes, ductile iron pipe sizes and dimensions, ductile iron pipe od, cement lined ductile iron pipe,

Post time: Nov-04-2025