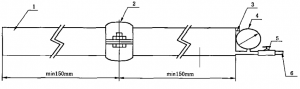

The torque test of grooved pipe fittings aims to systematically evaluate the mechanical performance and safety margin of grooved pipe fittings under torque load in complex pipeline systems, verify their torsional strength, structural stability and long-term reliability, and provide key data support for engineering applications such as fire protection pipelines and water supply and drainage systems. Install the experimental apparatus according to the drawings.

1. Pipe section 2. Grooved fitting 3. Vent port 4. Pressure gauge 5. Shut-off valve 6. Water injection/pressurization port

Significance of the torque test:

- Ensuring Engineering Safety: The experimental results directly guide the design and construction of critical systems such as fire-fighting pipelines and industrial pipelines, ensuring that grooved piping systems maintain structural integrity under extreme conditions of high pressure and vibration.

- Optimizing Product Design: Providing data feedback to grooved pipe fitting manufacturers helps in the development of grooved connection solutions with high torque capacity, enhancing the market competitiveness of clamp-type pipe fittings.

- Promoting Standard Upgrades: The experimental data can serve as a basis for revising industry standards (such as the CJ/T156 grooved pipe fitting standard), promoting the continuous improvement of grooved pipe fitting technical specifications.

Post time: Jan-20-2026