DINSEN Pipe focuses on pipeline business. With rich experience and advanced technology, its products include ductile iron pipes, cast iron pipes/ also named SML pipe, pipe fittings and coupling etc, which are widely used in infrastructure, construction ,water supplying, hotel, airport and energy. It is a reliable pipeline solution provider for many large projects.

Pipeline production process

1.Raw material smelting

The raw material pig iron for producing pipes and fittings.

Accessories require No. 15 iron and pipes require No. 20 iron.

The picture below is an electric furnace, which uses electricity to heat bread iron into molten iron.

Pig Iron

Electric Furnace

2.Centrifugal casting

Replace the corresponding diameter pipe mold for the centrifuge in advance as needed.

The molten iron is injected into the high-speed rotating centrifuge mold from the inside to the outside through the flow channel.

The amount of molten iron is calculated according to the diameter of the cast pipe.

After the pipe is formed and cooled, it will be pulled out of the pipe mold, and the quality inspector will check the appearance and weigh it. Qualified ones will proceed to the follow-up work.

The mold of the pipe is larger than 3 meters, which is convenient for cutting the unevenly formed parts of the head or tail later.

Centrifuge

3.Pipe cutting, inspection, and polishing

After selecting qualified pipes, the workers will cut the unevenly formed parts at the head and tail to keep the effective length of the pipe at 3m.

After the cutting is completed, another inspection will be carried out to select pipes with uneven wall thickness and elliptical deformation for re-melting.

Polishing requires polishing both inside and outside of the pipe to ensure that the inside and outside are smooth and convenient for subsequent painting.

Grinding Machine

4.Internal and external spraying

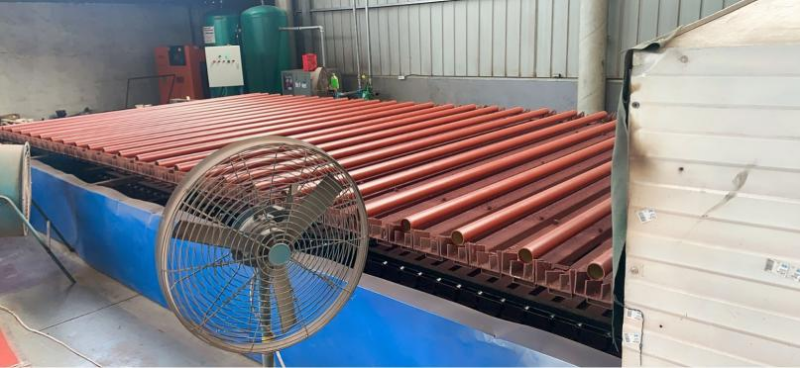

The inner wall of the polished pipe must be kept particularly smooth and clean. After drying and heating, the inner wall is treated with anti-corrosion, that is, sprayed with yellow epoxy paint.

The same operation is also performed on the outside, sprayed with reddish-brown epoxy paint.

The factory will regularly sample and spot check a batch of products to ensure that the product properties meet the requirements of EN877.

5.Drying, trimming, spraying, packaging

After spraying the paint inside and outside, the pipe will be dried to ensure the adhesion of the paint.

After drying, the workers will repair the paint on the pipe, especially the two ends, to ensure the coverage and beauty of the paint.

Finally, the pipe will be sprayed with the customer's trademark and packaged according to the customer's habits.

Dryer

Accessories production process

1.Mould preparation

DINSEN currently have moulds of all models and specifications. Each time the factory arranges production, the casting and batch number in the mould must be changed, and then the workers can start production after getting the mould.

2. Manual pouring, Automated pipe production line

The workers put the upper and lower molds on the flat plate, put the sand box on it, fill it with sand, compact it, and scrape it flat. Then they put the upper and lower molds together and fix them, and after pouring molten iron, they are formed in one go.

Each worker can produce an average of 300KG of pipe fittings per day, because frequent mold changes not only affect the factory's production schedule but also directly affect the workers' output.

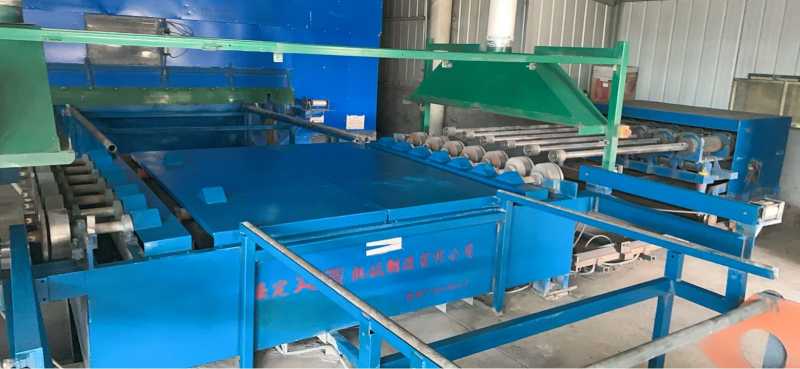

Automated pipe production line, manual pouring

Compared with the traditional manual sand casting process, its biggest feature is that it can minimize the consumption of manpower and material resources, and maximize production efficiency, ensuring that product quality meets standards and specifications are unified, which can greatly improve production efficiency and shorten product production cycle.

3.Manual grinding

Under the premise of ensuring the external dimensions of the parts, the workers must remove the gates, risers, flash, burrs and the molding sand on the surface by grinding. The lack of meat caused by insufficient casting, keyholes or sand cleaning must also be repaired. Ensure that the impurities on the surface of the casting are clean and polished before subsequent spraying.

4.External wall polishing, Inner wall grinding, Fine grinding

5.Painting, powder coating, packing

Paint dipping: You need to preheat the pipe fittings to 70-80℃ and spray epoxy paint.

Powder spray: You need to preheat the pipe fittings to 180-200℃ before spraying epoxy powder.