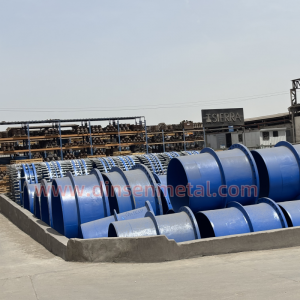

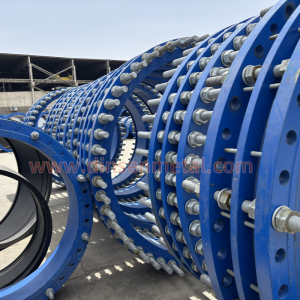

On the eve of the WATEREX EXPO Egypt exhibition, Bill went deep into the local area and made an in-depth visit to a local ductile iron pipe factory with considerable strength. The factory focuses on the production of ductile iron pipes, ductile iron pipe fittings and ductile iron valves. With its excellent production management system, the factory has performed well in product quality control, and the various cast iron products it produces have won a good reputation in the local market. However, in terms of pipe fitting production technology, it still adopts a more traditional method, which to a certain extent limits the improvement of production efficiency and product precision. It is worth noting that the factory has keenly perceived the advantages of China’s advanced casting technology and is actively trying to introduce lost foam casting technology, striving to achieve innovation and breakthroughs in production technology.

The traditional resin sand casting process has been the mainstream technology for the production of ductile iron pipe fittings for a long time in the past. It uses resin to bond sand particles into shape, and then destroys the sand mold to remove the casting after the casting is formed. This process not only produces a large amount of waste sand, but also easily causes environmental pollution if improperly handled. In addition, the production process is relatively cumbersome. From mold making, modeling to cleaning, each link requires a lot of manpower and time, which is difficult to meet the needs of rapid production. In contrast, DINSEN’s lost foam process shows significant advantages. The lost foam process uses expandable polystyrene materials to make models. When casting, the models evaporate and disappear when exposed to high temperatures. There is no need for subsequent sand cleaning steps, which greatly simplifies the production process and improves production efficiency. At the same time, this process reduces the generation of waste sand, is more environmentally friendly during the production process, and is in line with the sustainable development concept advocated by the world today.

Globalink, a subsidiary of DINSEN, as a professional comprehensive service provider, has always been committed to providing one-stop supply chain solutions for global customers. With many years of experience in ductile iron pipes, Globalink exports ductile iron pipe fittings and equipment to complete the early overseas factory construction, high-speed centrifuges, etc., and provides services such as sea transportation logistics, land transportation, roll-on/roll-off ships, and exports ductile iron production technology, such as centrifugal casting technology.

In general, in terms of business, Globalink can provide a full range of services from the source control of raw material procurement, to real-time follow-up of production progress, to strict quality control, meticulous factory quality inspection, and logistics links such as warehousing, booking, loading, and transportation.

In the process of helping Chinese factories expand overseas, Globalink helps Chinese factories’ advanced technologies and equipment take root in overseas markets, promoting technological exchanges and industrial upgrading in the global foundry industry.

#greensandcasting #lostformcasting #ductileironpipefittings #supplychainmanagement #qualityinspection #centrifugalcasting #pipefittings #valves

Post time: May-14-2025