-

How to do Water Tightness Test for Ductile Iron Coupler |EN877:2021

The primary purpose of a Ductile iron coupler water tightness test is to verify leakage under specified pressure and ensure its sealing performance meets operational requirements. This prevents the transported liquid or gas from leaking out of the piping system. This water tightness test not only...Read more -

How to do Water Tightness Test for Fittings with Access or Door |EN877:2021

This test shall be carried out at ambient temperature on coated products on at least one DN by type of SML fitting and by group of DN defined in Table 9. The test assembly shall be capable of providing water tightness and lateral restraint on each end of the fitting for the required internal hyd...Read more -

How to do Adhesion Testing and Water Circulation Testing |EN877:2021

Cast iron pipes undergo adhesion testing and hot and cold water cycling tests in accordance with EN877, primarily to assess the long-term reliability and durability of their anti-corrosion coating systems, particularly under actual operating conditions. These tests typically target coatings appli...Read more -

How to do Salt Spray Testing and Resistance to Wastewater |EN877:2021

The primary purpose of salt spray and wastewater resistance testing for SML PIPE coatings in EN877 is to evaluate the coating’s long-term resistance to chemical corrosion (acids, alkalis, salts), electrochemical corrosion, and microbial corrosion by simulating harsh, real-world corrosive e...Read more -

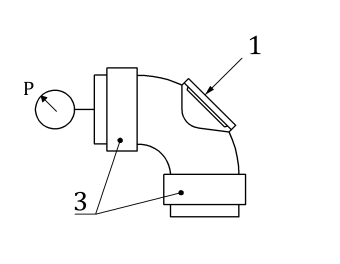

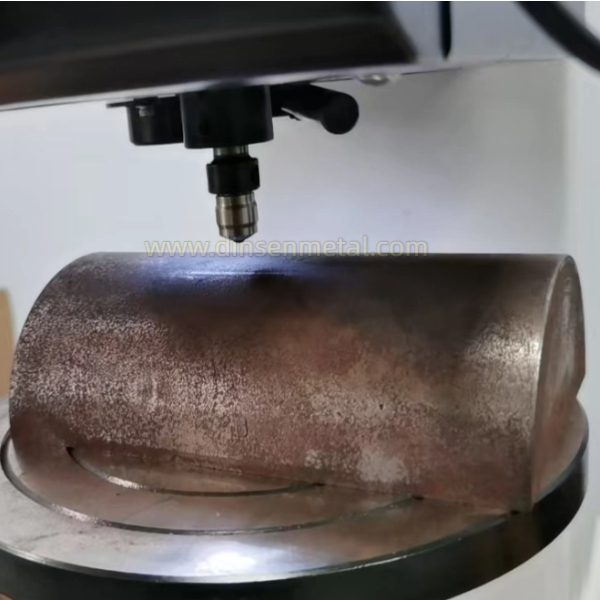

How To Do SML Pipe Brinell Hardness Test According To EN877?

The Brinell hardness test shall be carried out in accordance with EN IS0 6506-1, on the outer face of either sml pipes or a sample taken from the SML cast iron pipe.The surface to be tested shall be suitably prepared by means of light local grinding and the test results shall conform to Table 1. ...Read more -

How to do SML Pipe Tensile Test according to EN877?

For products made of spheroidal graphite cast iron the tensile strength shall be measured in accordance with EN 598:2007+A1:2009, 6.3. For products made of grey cast iron or any other type of cast iron the determination of tensile strength shall be carried out in accordance with 2 or 3. Define te...Read more -

What is EN13501-1:2018 (DS SML PIPE A1)

EN13501-1:2018 is one of the most important European standards for the classification of fire performance of construction products. Its full name is: EN 13501-1:2018 Fire classification of construction products and building elements – Part 1: Classification using data from reaction to fire ...Read more -

How to do Cast Iron Pipe Hardness Test

DINSEN Cast iron pipes serve as critical infrastructure for conveying fluids such as water and gas. Their performance directly impacts the safety and lifespan of engineering projects. Hardness and tensile strength are core indicators for measuring their quality, and rigorous experimental testing ...Read more -

How to Choose Ductile Iron Pipe According to Its Advantages

APPLICATIONS OF DUCTILE IRON PIPES are utilized in a broad range of applications, owing to their robustness and flexibility: . Water Supply and Distribution: Their excellent pressure and impact resistance makes them ideal for water mains,distribution lines, and pumping stations. . Sewer and Wast...Read more -

The Difference between A1 and A2 Coatings of Cast Iron Pipe

In cast iron pipe coating standards of A1 and A2 levels in the relevant fire protection levels, which can be used to evaluate the fire resistance of building materials such as paint. The differences between A1 and A2 paints are as follows: Different test standards A1 paint: must pass both non-fl...Read more -

Why Coastal Cities Choose Cast Iron Drainage Pipes

In coastal cities and high-humidity areas, the durability of the drainage system is directly related to the safety and operation and maintenance costs of urban infrastructure. Typical coastal cities such as Hong Kong and Singapore face erosion from high-salt air and humid climate all year round. ...Read more -

Cast Iron Pipe colors and Special Requirements of Markets

The color of cast iron pipes is usually related to their use, anti-corrosion treatment or industry standards. Different countries and industries may have specific requirements for colors to ensure safety, corrosion resistance or easy identification. The following is a detailed classification: 1. ...Read more

© Copyright - 2010-2024 : All Rights Reserved by Dinsen

Featured Products - Hot Tags - Sitemap.xml - AMP Mobile

Dinsen aims to learn from world famous enterprise like Saint Gobain to become a responsible, trusty company in China to keep improving the human being life!