DINSEN IMPEX CORP has long been adhering to the quality control, and to assist customers to achieve the British BSI kite certification.

What is the UK BSI Kite Certification?

As a third-party certification body, BSI’s auditors will focus on auditing the parts that customers pay more attention to according to the specific requirements of customers. Whether the audit is passed or not is in the hands of the customer, but BSI auditors will never give the factory a green light if they find that the factory has violated the “zero tolerance” standard.

This certification is the highest international standard quality certification and is also one of the certifications many factories’ products need to go through. The quality of products that obtain this certification will be recognized internationally.

On the 26th, the company went to the factory to assist customers and BSI certifiers to complete the quality test.

1. Pipe fittings sample test

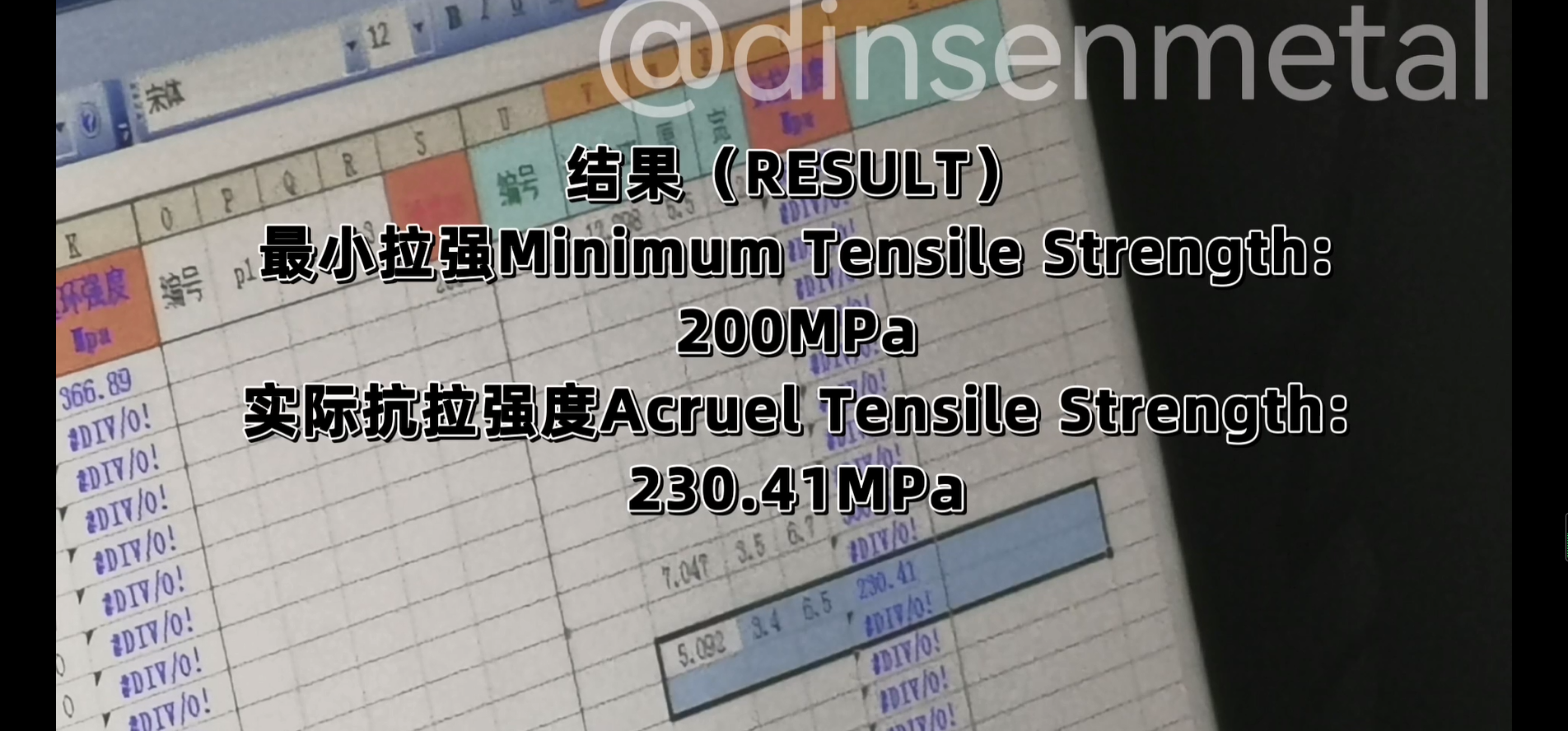

A. Tests of tensile strength

The factory is equipped with professional testing personnel to extract samples from customers’ pipes and fittings in advance and operate on the instruments respectively. The computer records the instrument data, and the inspector then comprehensively calculates the sample thickness and other data to obtain the final tensile strength. The BSI certification is 200MPa, and the actual measurement is 230.41MPa.

B. Pressure Test

To test the pressure strength of the pipeline, the pipeline in real life, there may be pressure from multiple factors, such as wall extrusion, heavy object downward pressure, etc. This test is to test the service life of the pipeline in different scenarios. The BSI requires a minimum pressure ring strength of 350MPa, and the actual measured strength can reach 546MPa.

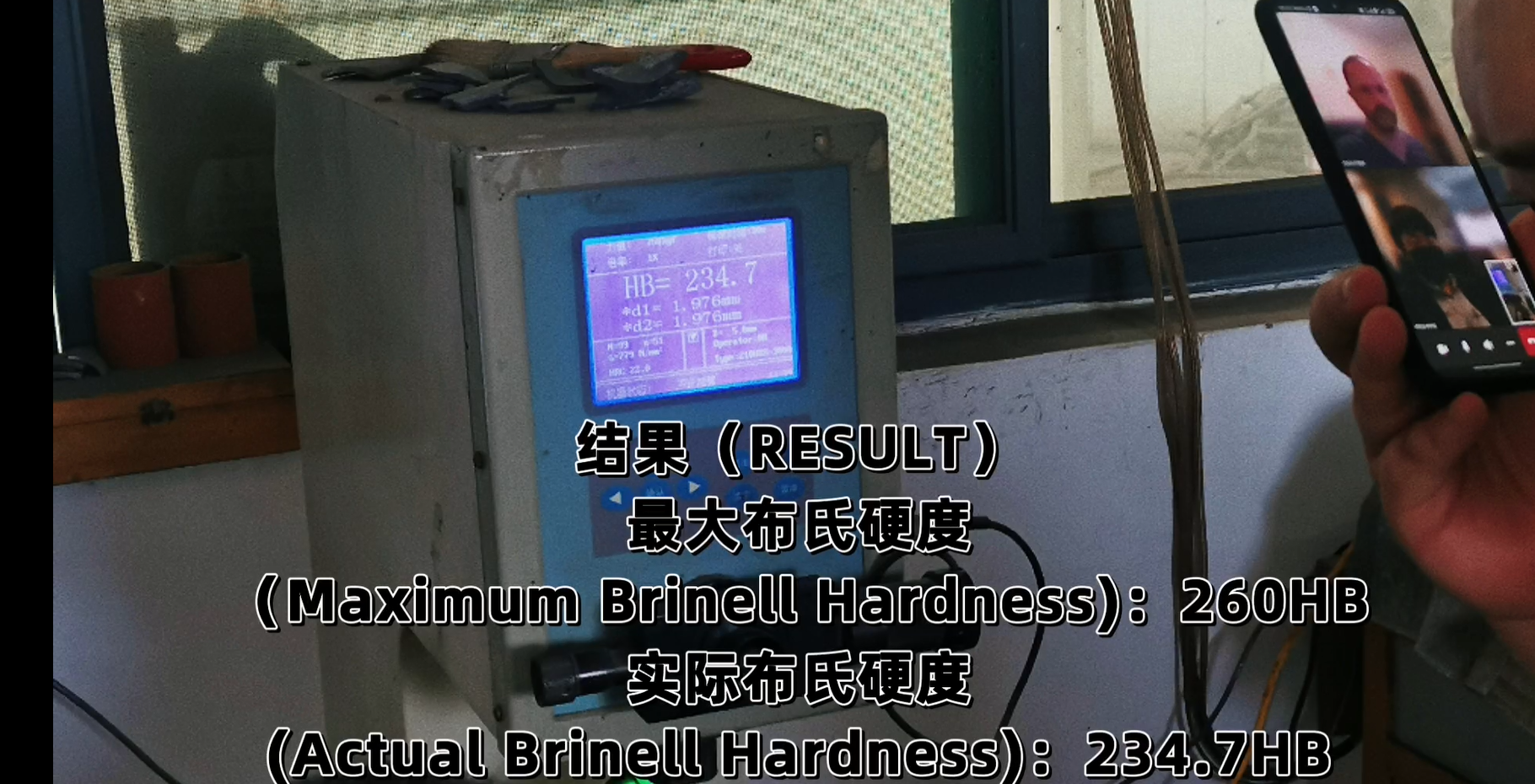

C. Buchenne hardness test

The brinell hardness test is the same as the previous two tests, in order to test the affordability of the materials and quality of the product. BSI certification requires a maximum cloth hardness of 260HB and the actual measurement of 230.4HB.

2. Stainless Steel Coupling air tightness test

A. Straight Angle of water pressure and air pressure test

The test is through the professional operation, the pipeline water injection, pump, respectively in the water pressure reached 0.5, the air pressure reached 1.5, wait in this state for 15 minutes, to see whether there is water seepage at the clamp connection, whether there are air bubbles after applying the detergent water, in order to prove the degree of the hoop air tightness.

B. Flexing water pressure test

In order to ensure the tightness of the clamp in any circumstances, the pipe section is oblique cut, using the Angle gauge to measure 3 Angles, the cut with the clamp connection, the water pressure to reach 0.5 again, 15 minutes to check whether the water seepage at the clamp connection, not to pass the test.

Strength and hardness test can help customers to intuitively feel the quality of pipe fittings with data. Water pressure test can make customers intuitively verify the tightness of the clamp. The BSI certification is a proof of product quality up to European standards. Help customers in the pipeline market occupy stable quality positioning, effectively achieve the purpose of helping customers to maintain brand reputation, with quality as DINSEN spread the core of the Chinese cast iron pipe, is our positioning for a long time, also hope to adhere to this position to help more customers in the market development for a long time, let the world impression of China cast iron pipe no longer stay on the characteristics of large quantity, low price.

Post time: Oct-31-2022